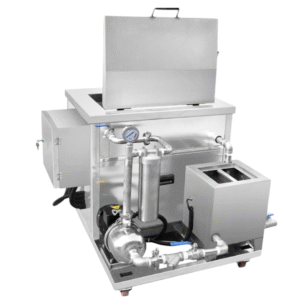

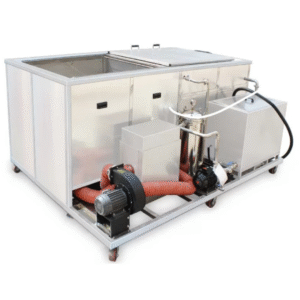

Description

Product Features:

- Greater conversion ratio of ultrasound wave power, accelerated cleaning, and cleaning efficiency several times higher than traditional methods.

- Outstanding cleaning efficiency, superior cleanliness, and effective removal of dirt from hard-to-reach areas like holes and seams.

- Sanitization of workpiece, removal of organic impurities, and prevention of corrosion.

- Production of premium embossed stainless steel featuring superior rust resistance and appealing aesthetics; cleaning tank constructed from high-grade SUS316 stainless steel, press-formed without welding seams and completely watertight.

- Temperature for cleaning can be adjusted from 20 to 80???, with operating time shown and regulated by a Digital Temp controller, ranging from 0 to 999 minutes to accommodate diverse cleaning requirements.

- Drain and heat sink included for rapid removal of wastewater post-cleaning.

- Cleaning basket designed with a stainless-steel 304 mesh screen for convenient use.

- A secure and dependable cleaning method that requires no manual effort and does not harm the surface of the workpiece, utilizing less solvent, thermal energy, space, and labor.

Scope of Application:

- Machinery: Elimination of oil/grease from parts and components, cleaning of engine, carburetor, and vehicle parts and components, filter, and filter mesh.

- Surface preparation: Elimination of oil and corrosion prior to galvanic coating, cleaning and phosphating procedures before ion plating, removal of built-up carbon, scale, and polishing compound, activation of the workpiece surface.

- Instrumentation: sanitation of measurement instruments and meticulous cleaning of precision components before assembly.

- Electronics: Elimination of rosin and solder residues on printed circuit boards, along with the cleaning of high-voltage contacts and additional electronic components.

- Healthcare: Sanitation, disinfection, and sterilization of medical instruments and laboratory glassware.

- Semiconductor: Precision cleaning of semiconductor wafers.

- Watches and jewelry: Elimination of grime, dirt, residue, and polishing compound.

- Chemicals and biologicals: Sanitation of laboratory glassware.

- Optics: Cleaning optical elements and lenses.

- Dyeing and finishing textiles: Maintenance of spinning spindle and spinneret.

- Petrochemicals: Cleansing of metallic filtration mesh, chemical vessels, and heat exchangers.

Reviews

There are no reviews yet.