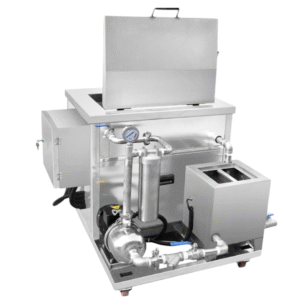

Description

Product Features:

- Increased ultrasonic wave power conversion efficiency, quicker cleaning, and significantly improved cleaning effectiveness compared to traditional methods.

- Superior cleaning efficiency, remarkable cleanliness, and effective cleaning of hard-to-reach areas like holes and seams.

- .

- Sterilization of the workpiece, removal of organic contaminants, and protection against corrosion.

- Production of premium embossed stainless steel featuring superior rust resistance and attractive design; cleaning tank constructed from high-grade SUS316 stainless steel, pressed into shape without welding seams and fully watertight.

- Cleaning temperature can be set between 20 and 80°C, while the operating time is shown and managed with a Digital Temp controller, ranging from 0 to 999 minutes to accommodate different cleaning requirements.

- Drain and heat dissipation system included for rapid release of wastewater following cleaning.

- Basket for cleaning with a mesh screen made of stainless steel 304 for convenience.

- A secure and dependable cleaning method that requires no human intervention and does not harm the surface of the workpiece, utilizing reduced amounts of solvent, thermal energy, spatial area, and labor.

Scope of Application:

- Machinery: Elimination of oil/grease from components and parts, sanitation of engine, carburetor, and auto parts and components, filter, and filter mesh.

- Surface processing: Elimination of oil and rust prior to galvanic coating, cleaning and phosphating steps before ion plating, removal of built-up carbon, scale and polishing compound, surface activation of the workpiece.

- Instrumentation: sanitizing measuring instruments and thoroughly cleaning precision components before assembly.

- Electronics: Elimination of rosin and solder marks on printed circuit boards and sanitation of high-voltage contacts and other electronic components.

- Healthcare: Sanitization, disinfection, and sterilization of medical instruments and laboratory glassware.

- Semiconductor: Precise cleaning of semiconductor wafers.

- Watches and jewelry: Elimination of grime, dirt, buildup, and polishing compound.

- Chemicals and biologicals: Washing laboratory glassware.

- Optics: Maintenance of lens and optical elements.

- Textile dyeing and finishing: Cleaning of the spinning spindle and spinneret.

- Petrochemicals: Cleaning metal filter mesh, containers for chemicals, and heat exchangers.

Reviews

There are no reviews yet.