Ultrasonic cleaning ensures thorough cleanliness, saves time, reduces manual effort, and extends the lifespan of components—all while being eco-friendly.

- Home

- Company Profile

- Products

- Ultrasonic Cleaners

- Industrial Single Stage Ultrasonic Cleaner

- Table Top Ultrasonic

- Ultrasonic Mold Cleaning Machine

- Medical Ultrasonic Cleaner

- Muti Stage Aqueous Ultrasonic Cleaners

- Automotive Ultrasonic Cleaner

- PCB Cleaning Machine

- Aluminium Cleaning Chemical

- Anilox Roller Cleaning Machine

- Brass Cleaning Chemical

- Degreasing Chemical

- Gas Valve Cleaning Machine

- Immersible Transducer Box

- Multi Stage Vapour Degreaser

- Blog

- Contact Us

- Home

- Company Profile

- Products

- Ultrasonic Cleaners

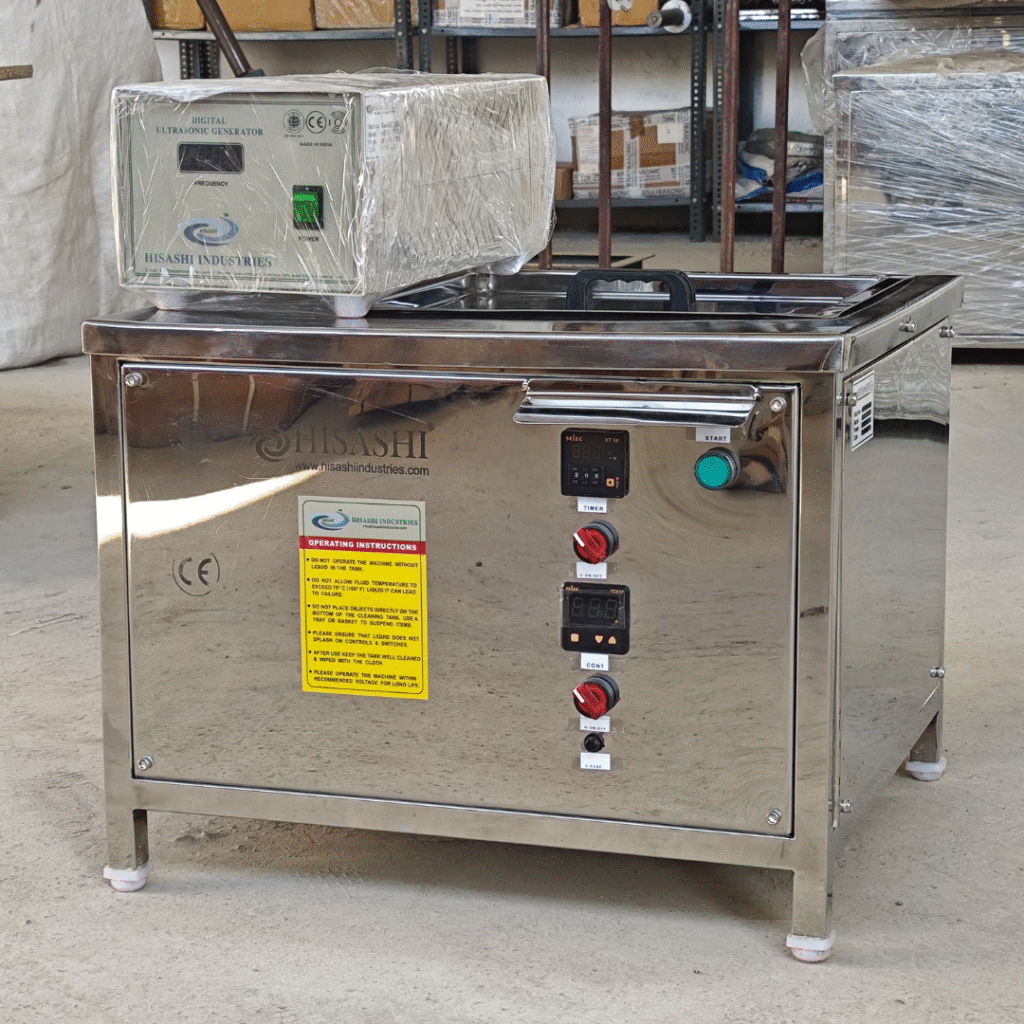

- Industrial Single Stage Ultrasonic Cleaner

- Table Top Ultrasonic

- Ultrasonic Mold Cleaning Machine

- Medical Ultrasonic Cleaner

- Muti Stage Aqueous Ultrasonic Cleaners

- Automotive Ultrasonic Cleaner

- PCB Cleaning Machine

- Aluminium Cleaning Chemical

- Anilox Roller Cleaning Machine

- Brass Cleaning Chemical

- Degreasing Chemical

- Gas Valve Cleaning Machine

- Immersible Transducer Box

- Multi Stage Vapour Degreaser

- Blog

- Contact Us

- Home

- Company Profile

- Products

- Ultrasonic Cleaners

- Industrial Single Stage Ultrasonic Cleaner

- Table Top Ultrasonic

- Ultrasonic Mold Cleaning Machine

- Medical Ultrasonic Cleaner

- Muti Stage Aqueous Ultrasonic Cleaners

- Automotive Ultrasonic Cleaner

- PCB Cleaning Machine

- Aluminium Cleaning Chemical

- Anilox Roller Cleaning Machine

- Brass Cleaning Chemical

- Degreasing Chemical

- Gas Valve Cleaning Machine

- Immersible Transducer Box

- Multi Stage Vapour Degreaser

- Blog

- Contact Us

- Home

- Company Profile

- Products

- Ultrasonic Cleaners

- Industrial Single Stage Ultrasonic Cleaner

- Table Top Ultrasonic

- Ultrasonic Mold Cleaning Machine

- Medical Ultrasonic Cleaner

- Muti Stage Aqueous Ultrasonic Cleaners

- Automotive Ultrasonic Cleaner

- PCB Cleaning Machine

- Aluminium Cleaning Chemical

- Anilox Roller Cleaning Machine

- Brass Cleaning Chemical

- Degreasing Chemical

- Gas Valve Cleaning Machine

- Immersible Transducer Box

- Multi Stage Vapour Degreaser

- Blog

- Contact Us